- Stroke engine

- Turbo compressor

- diesel generator

- Fuel equipment

- Filter, filter element

- Bearings, belts, seals

- Double tube seals, clutches, reducers

- Air compressor, refrigeration compressor

- Separator

- Seawater desalination plant

- Accessories for remote control valve

- Pump and pumping station

- Sewage treatment system

- Ventilation and air conditioning

- Crane, beam crane

- winch

- Wire rope

- Deck equipment

- Hydraulic equipment

- Porthole, door, latch

- Wall panels, furniture

- Automation and electrical equipment

- Fire and rescue equipment

- Oil, antifreeze and freon (refrigerant)

- Paints and varnishes

- Marine chemicals

- Living equipment

- Marine pressure washer

- Internal combustion engine high pressure washer

- Chain type rust remover

- Fog flute

- Gangways and ladders

- Ballast water management system

- Other equipment and parts

Double tube seals, clutches, reducers

×

![]()

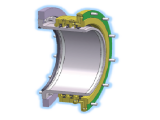

Stern shaft tube device Since the propeller began to be used as the propeller of a ship, there has been a problem of ensuring the water tightness of the hull in the outlet area of the propeller shaft.In addition, the stern shaft tube device is also used as a propeller shaft support.In principle, it consists of a rigid stern shaft tube, in which the bearing is fixed, and the stern shaft has stern shaft seals at both ends of the tube (closed system) or one inner end (water-based lubrication system).Different companies have developed several types of stern shaft tubes (DU).Rolling bearings are not common in remote controls, although some people tried to use them in the 1930s.Plain bearings have become the main bearings, and they are divided into non-metallic bearings and metal bearings.As materials for non-metallic bearings, buckout (Guaiac wood), textolite, wood laminated plastic, caprolon, caprolon, caprol, rubber metal (Maprom Engineering's Goodrich bushing or Romor strip), rubber ebony section and some other materials are used.This kind of bearing is lubricated and cooled with water.The bow and stern seals used in such devices are usually mechanical. They are oil seals with gaskets and pressure sleeves that prevent seawater from entering the ship.A seal is also used, which uses the sliding principle of the ends of two bushings with anti-friction coatings, which are pressed against each other by springs. Oil-lubricated stern tube bearings under pressure The metal bearing shell is filled with Pap alloy.They are lubricated with mineral oil at low pressure, in this case, the seals are rubber fabric cuffs with special contours.The design is a sleeve that surrounds the propeller shaft, and the propeller shaft is equipped with several cuffs to separate the oil chamber from the sea water chamber.Several chambers are responsible for separating the media; usually, the middle one is open on the bilge of the machine and is used as a control chamber.When a leak occurs, both oil and water are discharged into the bilge well or storage tank to collect the leak. Such devices include the “Simplex” type stern shaft tube seal developed by the German company Blohm + Voss Industries (BVI) in 1948.It has been widely used on medium and large-tonnage ships. Today, more than 50,000 “Simplex” seals of various modifications are installed on ships of various types and sizes in the world's fleet.In 1980, the new brand “Supreme” of the Dutch company IHC Lagersmit appeared in the stern shaft pipe seal market, and its design uses the same principle.On modern large-tonnage ships, the circulating lubrication of the first and second-generation oil, stern and bow seals for stern shaft pipes, such as “Simplex”, “Simplex-compact”, “Supreme”, “Vaukesha”, “Neptune”, “Cedervall”, “Deep Sea Seals”, etc., have proven themselves well. At present, the requirements for environmental protection have become more stringent.In order to prevent stern shaft oil from entering the sea, some manufacturers have begun to use additional “air locks” in traditional seals.Therefore, the oil and water are separated by an additional gas chamber.This device is used for stern shaft tube seals “Simplex-Compact 2000 Airspace“, ”Supreme Ventus“, ”Airguard 3AS JMT Marine Seals" and so on. The shortcomings that can be determined in the process of stern shaft tube sealing are typical for any system of this type, including the fragility of the material first.During operation, the surface will wear out, resulting in the risk of leakage.In addition, the technology is very sensitive to the entry of sand and other abrasive particles.Therefore, we recommend only purchasing high-quality stern shaft pipe seals designed and produced by leading companies.The loss caused by the failure of the stern shaft tube device is many times higher than the cost of the parts to be replaced.Towing costs, unplanned terminal repairs, loss of profits caused by downtime-this is not a complete list of costs in such accidents.The working time between the docks of the ship depends to a large extent on the condition of the bearings and seals of the stern wood. We only let you buy products that the employees of “Dalian Lanwan international trade” believe in their quality and reliability through their own experience.If you doubt the convenience of purchasing this equipment, please contact our experts for advice and we will work together to find the best solution for your ship.We look forward to your call and order!